There’s something about spiders… Despite the numerous spider decorations that will appear on and around houses this October, spiders remain high on many people’s list of “least favorite animals.” Nevertheless, spiders have some amazing traits. They can travel hundreds of miles on the wind. They can sense minute vibrations with their legs. And they synthesize a substance that, like mithril in Lord of the Rings, is tough, flexible, and shiny: spider silk.

The silk we are most familiar with from its use in fabrics is silkworm silk, spun by caterpillars of the silkworm moth to construct their cocoons. All spiders also produce silk, which they use for webs, egg sacs, draglines, and other purposes. Different kinds of spiders–there are more than 600 species in Ohio–build webs with a variety of structures, from funnels and bowls to classic spoked orb webs. The silk from orb weavers, represented locally by the orchard orbweaver, garden spiders, arrowhead orbweaver, and others, is the variety that has been characterized most extensively.

It turns out that orb weavers synthesize several types of silk, each with particular properties and deriving from separate glands. The major accessory (MA) gland secretes the largest diameter silk (MA silk; about 5% the diameter of human hair), which is used to build the primary framework of the web and which has been studied the most. The web’s rings are built from thinner “flag silk” secreted from the flagelliform glands. Neither of those silks is sticky; the glue that helps to catch prey is an organic concoction secreted from yet a third gland, the aggregate silk gland, and coated onto certain of the silk capture threads.

Technically, spider silks are called spidroins, and they constitute a class of large protein molecules. Like all proteins, spidroins are constructed as chains of amino acids, like beads on a string. The specific amino acids and their sequences within a protein cause the molecules to fold into complex three-dimensional shapes that determine the protein’s properties. Spidroins are unusual in that they contain long sequences rich in two particular amino acids (out of the 20 common protein building blocks), glycine and alanine. Interactions between those amino acids generate three-dimensional protein shapes (which are microscopically present within the visible silk thread) that are responsible for the strength of silk fibers. In contrast, other regions of the proteins contain different combinations of amino acids whose interactions and resulting folding patterns confer elasticity.

Although we experience spider silk as long, thin threads, spidroins exist in liquid solution while they’re within the silk glands. That changes during the process of “spinning,” as the silks are extruded through the glands’ ductways. Some combination of factors, likely including both the mechanical stress of passing through those narrow pathways and the chemical environment within the ducts, induces the transformation from amorphous liquid to thread-like solid.

The fascination with spider silks derives at least in part from their amazing physical properties. Spider silk is notably tough; on a weight-for-weight basis, MA silk can absorb more than three times as much energy as Kevlar (one of the toughest synthetic materials) before rupturing. Synthetic materials do tend to have higher tensile strength (the amount of force required to pull until breakage) than natural materials; Kevlar has about four times the strength of MA silk. However, natural materials tend to be more extendible; MA silk can extend in length 10 times as much as Kevlar, and flag silk is 100 times as extendible. In addition, spider silk resists twisting; a spider that drops on its line rarely spins. The combination of all of these factors creates a tough, flexible, durable capture device that withstands environmental challenges like wind as well as the forces of incoming prey items.

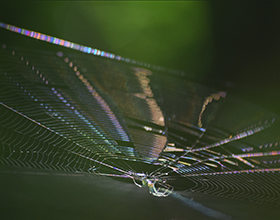

One more property of spider silk is notable. That is, the small diameter fibers in a web interact with sunlight in complex and remarkable ways. A combination of refraction and diffraction, interacting with a web that includes several silk varieties and structures, produces interference patterns that create amazing color patterns. These are difficult to see with the naked eye. But photograph a shimmering cobweb, especially backlit against a dark background, and your image may well reveal banding patterns in a dazzling array of colors. This may be of no use to the spider (are they even aware of the light show surrounding them?), but it’s fantastic to observe.

Given their exceptional material properties, along with the fact that spidroins are highly biocompatible (they are biodegradable and induce little immune reactivity), it’s no surprise that there is strong interest in harnessing spider silk for commercial applications. Potential uses include wound dressing, drug delivery, textiles, filters, and more. Silkworm silk, which lacks spider silk’s versatility, is produced on a commercial scale. Why not spider silk? The simple answer is the challenge to cultivating spiders and harvesting their silk. Put a bunch of silkworm moths on some mulberry trees and their caterpillars spin cocoons that can be collected and unwound. On the other hand, growing spiders in large numbers is not so easy (they tend to cannibalize each other), and extracting or collecting their silk is tedious and challenging. Instead, industrialists have turned to biotechnology for a possible solution. Efforts are underway to induce a variety of organisms to produce spider silk through genetic manipulation (so-called recombinant silk), ranging from bacteria and fungi to plants and mice. Although there have been modest successes, production sufficient for commercial use has not yet been achieved.

As spiders have their “season of glory” this October, we may not all come to love these eight-legged creatures. But it’s worth recognizing that spiders have some serious superpowers, and spider webs house secrets that we’re just beginning to unravel. Got silk?

Article and photo contributed by Dr. David L. Goldstein, Emeritus Professor, Department of Biological Sciences, Wright State University.